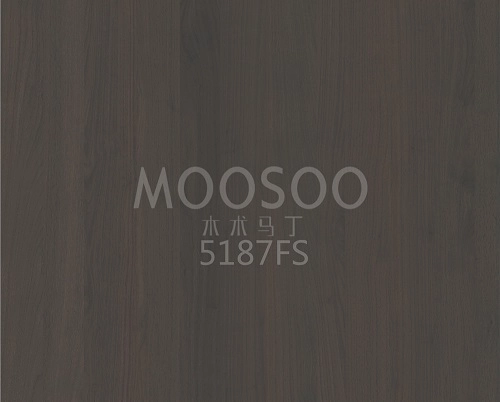

- White Elm: White elm is a hardwood species known for its distinctive, flowing grain patterns and warm, honey-toned colors. It’s prized in fine woodworking because of its beauty and strength.

- Wire-Brushing: Wire-brushing is a surface treatment technique where stiff wire brushes remove the softer wood fibers from the surface, highlighting the natural grain and texture. The result is a tactile, rustic finish that emphasizes depth and character while reducing surface sheen.

- Premium Panels: When we call these panels “premium,” we mean they are carefully selected for quality — with minimal defects, consistent thickness and grading, and often sustainably sourced. They can be veneer panels bonded to substrates such as MDF or plywood, or solid wood panels, depending on the application and budget.

- Visual Texture and Warmth: The wire-brushed finish gives the wood a rich, tactile surface that plays beautifully with light and shadow, adding depth and visual interest.

- Natural Aesthetic: White elm’s grain and color variations bring organic warmth into interiors, pairing well with both modern and traditional styles.

- Durability: Hardwoods like elm are strong and resilient. When properly finished, these panels resist wear and aging, making them suitable for high-traffic spaces.

- Versatility: These panels can be used in walls, ceilings, cabinetry, furniture, and other architectural features.

- Value: Premium materials often command a higher initial cost, but the longevity, beauty, and resale appeal they add can make them a worthwhile investment.

Common Applications

Interior Walls & Accent Features

Wire-brushed elm panels make striking statement walls in living rooms, dining areas, lobbies, or offices. Because the finish adds texture, they bring warmth to minimalist or contemporary spaces without feeling cold.

Ceilings

Used on ceilings, these panels introduce continuity and elegance, especially when coordinated with wall treatments or furniture.

Cabinetry & Built-Ins

Whether in a kitchen, bathroom, or home office, elm panels can be applied as cabinet faces or integrated woodwork to elevate ordinary storage systems.

Furniture

Furniture makers use these panels to create custom pieces like wardrobes, buffets, headboards, and shelving units.

Design Considerations

Color and Grain Variations

White elm ranges from light amber to deeper honey tones with bold, swirling grain lines. When selecting panels, consider whether you want uniformity or a more rustic, varied look. Arrange panels prior to installation to balance patterns and tones.

Panel Size and Orientation

Panels come in various widths and lengths. Vertical installations can make a room feel taller, while horizontal layouts emphasize width. Mixed orientations can create dramatic architectural statements.

Finish Choices

Natural oil or water-based clear sealer enhances grain and protects wood without altering color dramatically. Tinted or stained finishes can tailor the tone to specific palettes but may reduce natural variation.

Contrast and Complement

Pair elm panels with materials like matte black metal, stone, plaster, or painted surfaces for contrast. Complementary colors like soft greys, greens, or cream tones can amplify warmth.

Installation Guide

Tools and Materials You’ll Need

- Panels (prefinished or unfinished)

- Adhesive (if installing directly to substrate)

- Finishing nails or brad nails

- Level and measuring tools

- Saw (table or miter)

- Sandpaper (various grits)

- Sealant or finish (as needed)

General Steps

- Prepare the Surface: Ensure walls or substrates are clean, dry, and flat. Repair dents or irregularities.

- Acclimate the Wood: Store panels in the room for 48–72 hours to equalize humidity and reduce movement after installation.

- Plan Layout: Dry-fit panels to determine the most pleasing pattern, minimizing small cuts near corners.

- Apply Adhesive: If wall mounting without furring strips, use contact or panel adhesive recommended by the manufacturer.

- Fasten Panels: Press panels into place. Use finishing nails at panel edges or into furring strips. Countersink nails slightly.

- Finish Edges and Joints: Caulk or trim edges for a polished look. Touch up nails with wood filler if stained or unfinished.

- Apply Finish: If panels are unfinished, apply your chosen sealer or oil to protect the wood.

Tip: When installing in moisture-prone areas (e.g., kitchens or bathrooms), use engineered wood panels and seal edges thoroughly.

Care and Maintenance

Routine Cleaning

- Dust regularly with a soft cloth or microfiber duster.

- For deeper cleaning, use a damp cloth (not wet) with a mild wood cleaner.

Protecting the Surface

- Avoid abrasive cleaners or harsh solvents.

- Use coasters and pads on furniture to prevent scratches.

Re-Oiling or Refinishing

Over time, high-traffic areas may benefit from re-oiling to restore luster. Lightly sand before re-applying oil or sealer.